TMCnet News

Top 3 Trends Impacting the Global Sealing and Dispensing Robots Market Through 2021: TechnavioTechnavio's latest market research report on the global sealing and dispensing robots market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline. This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170721005502/en/

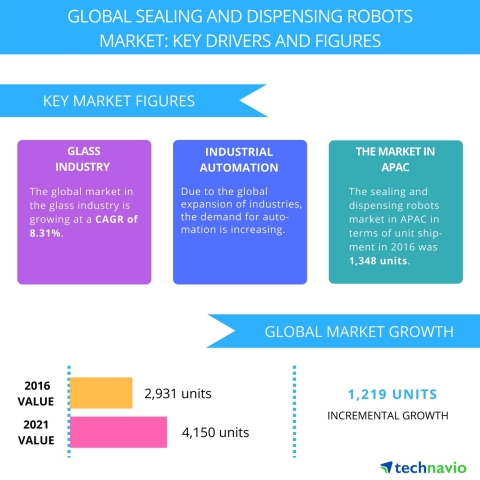

Technavio has published a new report on the global sealing and dispensing robots market from 2017-2021. (Graphic: Business Wire) This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free. The top three emerging market trends driving the global sealing and dispensing robots market according to Technavio research analysts are:

Looking for more information on this market? Request a free sample report Technavio's sample reports are free of charge and contain multiple sections of the report ncluding the market size and forecast, drivers, challenges, trends, and more. Flexible assembly lines and expansion in product line The rise in demand for robots has decreased the cost of electronic, electrical, and mechanical components used in the construction of robots. In addition, new assembly lines are emerging due to developments and growth in industries such as automotive and glass. Applications such as welding, picking and packaging, painting, sealing and dispensing, and inspection are critical applications that require quality. All these processes require the implementation of robots in industries. Sealing and dispensing robots are operated using PC software, where the user can pre-program the robot to apply sealants. However, these pre-programmed robots would not be able to work with objects of constantly changing shapes and sizes. Therefore, during the forecast period, it is expected that advances in technologies will enable these robots to become more flexible and work on objects with constantly changing shapes and sizes. These robots will become more flexible in their movements, enabling them to twist to different angles and inspect the objects more thoroughly. 3D multi-imaging and image scanning Sealing and dispensing robots are incorporated with cameras and sensors that help them to understand the complexity of the component design. This understanding allows sealing and dispensing robots to determine the workstation and apply the right quantity of sealant in the right space. "The need to improve work efficiency and quality will pave the demand for advanced industrial robots with new features. 2D and 3D multi-imaging and image scanning allow robots to capture multiple images from all dimensions which are analyzed to determine the right coating and quantity of sealants. Therefore, sealing and dispensing robots will be implemented in industries to help minimize errors and reduce wastage," says Sushmit Chakraborty, a lead analyst at Technavio for robotics research. Developing lighter weight vehicles Recent technologies in the automotive and auto component manufacturing industry include the development of lighter weight vehicles and components. Structural adhesives have enabled manufacturers to implement this technology. While applying adhesives and sealants on lightweight objects, it is important to note that robots should provide right viscosity and cure to adhesives. The right viscosity of adhesives applied on lighter weight objects and the time taken by adhesives to get harden are critical for lightweight components to stick together. "Robotic arms can move in multiple directions, and thus it needs to maintain the correct temperature and pressure. Keeping this on priority, OEMs need to develop advanced robots to address the demand for high precision. The forecast period will witness new developments in the robotics manufacturing sector, offering industries with speed and high-precision sealing and dispensing robots," says Sushmit. Browse Related Reports:

About Technavio Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions. With over 500 specialized analysts, Technavio's report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios. If you are interested in more information, please contact our media team at [email protected].

View source version on businesswire.com: http://www.businesswire.com/news/home/20170721005502/en/ |