There have been a great many rumors over the last few months that Apple (News  - Alert) is working on a new device that will put to use flexible glass. When we say “flexible glass,” we do not mean some sort of plastic that may look like glass but in fact isn’t. We specifically mean real glass that can now be made thin enough and flexible enough to literally bend into significantly curved shapes. Nor do we mean a sheet of glass that has just a tiny bit of flex to it – we mean exactly what we say – “completely curvable” glass.

- Alert) is working on a new device that will put to use flexible glass. When we say “flexible glass,” we do not mean some sort of plastic that may look like glass but in fact isn’t. We specifically mean real glass that can now be made thin enough and flexible enough to literally bend into significantly curved shapes. Nor do we mean a sheet of glass that has just a tiny bit of flex to it – we mean exactly what we say – “completely curvable” glass.

This new glass comes from no other than the legendary Corning (News  - Alert) Inc., the makers of, among numerous other glass products, the super tough Gorilla Glass used in many smartphones and tablets today. Apple, of course, loves the stuff, as any iPhone (News - Alert) 4 and 4S user will tell you. So do we – enough so that we will never put a case around our iPhone 4S. Our iPhone 5 isn’t nearly as jewel-like as our iPhone 4S in our humble opinion, though it is a lot lighter.

- Alert) Inc., the makers of, among numerous other glass products, the super tough Gorilla Glass used in many smartphones and tablets today. Apple, of course, loves the stuff, as any iPhone (News - Alert) 4 and 4S user will tell you. So do we – enough so that we will never put a case around our iPhone 4S. Our iPhone 5 isn’t nearly as jewel-like as our iPhone 4S in our humble opinion, though it is a lot lighter.

We’ve done some investigating into what a next generation curved glass iPhone might look like based on the ability to curve both displays and the glass that encloses such displays – there are many possibilities and directions that a Jony Ive can take iPhone and iPad hardware design in with curved displays. But…the real question, and the real rumor out there, isn’t about iPhones and Pads – it is of course about what Apple may have planned in the way of an iWatch.

Much has been made about the notion of linking an iWatch to curved glass, though in truth we’re not sure why. Is the underlying notion that Apple would only deliver an iWatch that is “curved” really reality? We kind of doubt it. There have also been rumors that Apple is working with man-made sapphire crystal – which as we know from the high-end mechanical watch world can indeed be shaped into all sorts of complex multi-axis curves. In truth, multi-axis curves on an iWatch strike us as much more of the Apple/Ive mantra than mere curved glass – which anyone, especially Samsung (News - Alert), can easily enough deliver on.

There is little point in speculating on what Apple might do with a future iWatch at this point in time. The bottom line is that it won’t only be a hardware exercise – it will also be a software exercise that will hopefully deliver multiple levels of innovation that will drive an iWatch. On the iPhone end of things however, flexible glass has more immediate and tangible possibilities – how about a curved smartphone as a wearable tech device? But even so, what Apple might do with such a capability isn’t the real news.

Corning has the Real News with Willow Glass

The real news is that there is even such a possibility at hand, and for that we must thank Corning and its visionary scientists and engineers who have made such a thing possible. Not only possible but in fact very real. Just about a year ago, on June 4, 2012, Corning announced that flexible glass is now a reality.

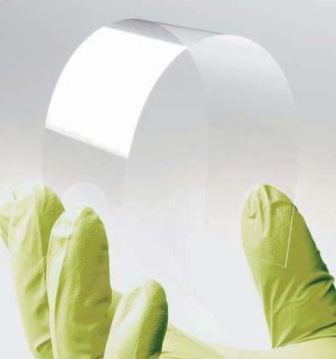

Dubbed Corning Willow Glass, the new product is an ultra-slim, flexible glass designed specifically for next-generation consumer electronic technologies that will range from light and cost-efficient applications that include both today’s ultra-thin slim displays and the smart surfaces of the future. The thinness, strength and flexibility of the glass have the potential to enable displays to be wrapped around a device or structure – something we see Apple as thinking about.

The key engineering accomplishment for Corning Willow Glass is that it can be processed at temperatures up to 500° C. This high temperature processing capability is critical for today’s high-end displays. It is a processing condition that cannot be supported with polymer films. What this means is that Corning Willow Glass will enable high-temperature, continuous roll-to-roll processes - similar to how newsprint is produced. That is something that was impossible to do before Corning Willow Glass appeared. Such a process means that manufacturing can be done at high speed and relatively lower cost.

As shown below, the level of curvature is quite amazing – again, keep in mind this is real glass we’re talking about it.

There is more to it, however, than simply delivering glass that can be curved. The glass must also deliver on other key specifications, especially those related to the electronic displays it will necessarily need to work with. Corning Willow Glass is formulated to perform exceptionally well for electronic components such as touch sensors, as well as leveraging glass’s natural hermetic properties as a seal for OLED displays and other moisture and oxygen-sensitive technologies.

This means that Willow Glass must support thinner backplanes and color filters for both organic light emitting diodes (OLED) and liquid crystal displays (LCD) – exactly those in found in high-performance portable devices smartphones, tablets, notebook computers and…how about smartwatches? There are other cool new applications for Will Glass that we ourselves are not directly focused on but that merit a mention. For example, Will Glass will be used to also develop conformable (that is Corning’s word but it means “curved”) displays for immersive viewing and/or mounting on non-flat surfaces. Corning also anticipates other applications for Willow Glass that include use in lighting and flexible solar cells.

Dr. Dipak Chowdhury, division vice president and Willow Glass program director at Corning, notes, “Displays become more pervasive each day and manufacturers strive to make both portable devices and larger displays thinner. Corning Willow Glass provides the substrate performance to maintain device quality in a thin and light form factor. Currently manufacturing in a sheet-to-sheet process, we expect Corning Willow Glass to eventually allow customers to switch to high-throughput, efficient roll-to-roll processing, a long-awaited industry milestone.”

Corning Willow Glass is produced using the company’s proprietary fusion process, which makes it possible for Corning to manufacture glass that is exceedingly strong and stable though a mere 100 microns thick – about the thickness of a sheet of copy paper. Corning is now shipping samples of its Willow Glass to customers developing new display and touch applications. The company also collaborates ongoing with research institutions, customers, and equipment makers to develop an ecosystem of compatible process equipment, including optimized process design.

The likelihood that we’ll see any actual curved shipping products in 2013 is somewhere between exceedingly slim and none. The following year – 2014 - however will bring us a bonanza of Willow Glass products. Patience is best here but we expect true next generation mobile devices – and perhaps a curved iWatch – to show up then, from both Apple and its key competitors.

Corning has provided a number of very interesting videos on Willow Glass. Below is a good example. Others are available on YouTube (News - Alert) for those interested in digging deeper.

Edited by Alisen Downey

Wearable Tech World Home

Internet Telephony Magazine

Click here to read latest issue

Internet Telephony Magazine

Click here to read latest issue CUSTOMER

CUSTOMER  Cloud Computing Magazine

Click here to read latest issue

Cloud Computing Magazine

Click here to read latest issue IoT EVOLUTION MAGAZINE

IoT EVOLUTION MAGAZINE